U.S. Steel Corporation will restart work on its electric arc furnace in Fairfield. The $215 million initiative will replace the former blast furnace at Fairfield Works. The project started almost four years ago, but was put on hold due to poor market demand for steel. Ty West, editor-in-chief of the Birmingham Business Journal, says this is good news.

Interview Highlights

What this means for Fairfield and surrounding areas affected by the steel industry’s downturn:

It’s a big deal for that area it’s going to be good for the employees. Obviously, it’s going to bring some employees back to work. It’s not going to salvage everything that we lost, but having 150 additional employees coming back online, that’s very, very big. But it’s also big because Birmingham has a nice concentration of metal companies and steel companies. So having this kind of critical mass of having a new furnace in our area that’s going to be good long term because that’s going to require people who service those types of facilities but it’s also good just going to be good for the many metals companies that work in this space to have U.S. Steel producing significantly more steel once again in our community.

Key factors in the project’s revival:

I think there are a few. One of them, they got a new labor agreement with the United Steelworkers. That happened late last year. The company had always said securing a new labor deal was a big part of what they needed to accomplish before they could revive this project. The other was better operating results. The steel market has improved over the past couple of years and they’ve been sending signals that reviving this project was possible for at least 18 months. They’ve been saying it’s a matter of when, not if. They’ve sounded more and more optimistic. Two weeks ago they announced their fourth quarter earnings. People on the conference call asked the CEO “what’s the status of the EAF project?” And he was sending very strong signals at that point that hey it’s on it’s on the horizon. They said they had hit basically the earnings results they needed to hit. They had the labor deal. The trade policies at the federal level had helped and they were getting close they said at that point on they were just trying to work out a few final local details with the union employees and it sounds like that’s happened.

The role of Alabama and Jefferson County in the revival of this project:

We know at this point that both Jefferson County and the state of Alabama, the Department of Commerce have given some incentives to U.S. Steel. They have not disclosed those incentives yet. We’re working to find those numbers but that’s pretty common of a project of this size. I mean you’re talking about a $200 million capital investment and 150 jobs. So it’s pretty typical of a project of that magnitude to get some incentives from local governments historically so we’ll see what those numbers turn out to be.

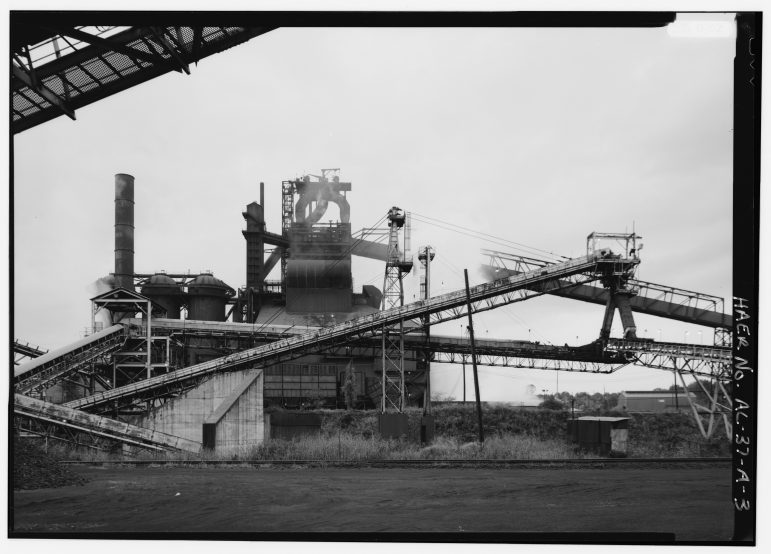

Major differences between the old furnace at Fairfield Works versus new EAF project:

An EAF, electric arc furnace, uses scrap metal to make steel. That’s a key component whereas the old method used in the blast furnace used several kind of natural greens including coal to make steel. So this will get us out of that using coal to make steel. You’ll focus more on using scrap metal, it’s just a more efficient way. If you look at the earnings for steel companies, the companies like Nucor that have been using this EAF model longer, they’ve traditionally been more efficient and had better profits in recent years. So it’s going to just continue the technological advancement of U.S. Steel.

On the potential for the steel industry’s revitalization in Birmingham:

You know the truth of the matter is we’re never going to get back to where we were. We’re not gonna get back to the day when we have 20,000 people working U.S. Steel in Fairfield and just thousands of thousands employees in the industry. But I think this project is a sign that perhaps maybe Birmingham can evolve with the steel industry. And perhaps this is a start of more investments by U.S. Steel in our community. I mean we still have a lot of advantages over some other areas that U.S. Steel operates. We have some good advantages in terms of logistics infrastructure in terms of affordability. So you’re hopeful that this is the first of many investments in Birmingham. And you hope that other companies that are in related industries will follow suit with this and you’ll have a little bit of building up around that critical mass that we have in the area. But U.S. Steel so far hasn’t committed to any additional projects, at least publicly.